Fire- & blast resistant cladding

Reliable solutions for extreme conditions

We offer quality cladding systems made from aluminium, galvanized steel, stainless steel 316L or Duplex stainless steel. Our materials are chosen for their durability, corrosion resistance, and superior performance. Cladding systems can be used for a variety of purposes: windshields, blast relief, heatshields, underdecks and louvres.

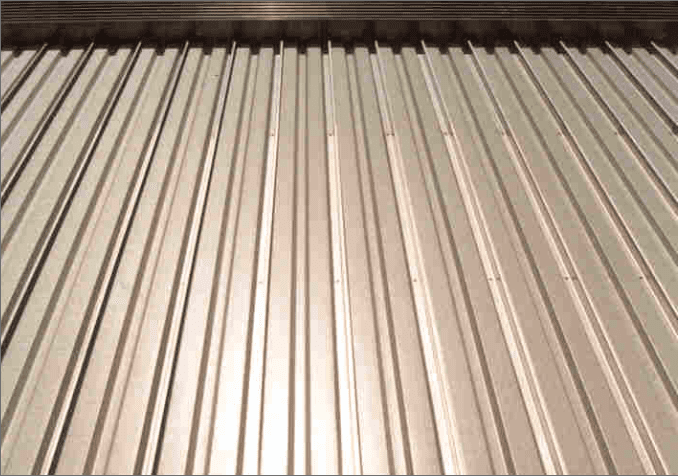

Windshield cladding

Standard windshield cladding is single-skin corrugated sheeting with standard profile height of 35 mm. This sheeting can easily be fixed to supporting rails with stainless steel, self-tapping bolts. Special gaskets can be used to separate dissimilar materials (where required) to avoid galvanic corrosion. The maximum unsupported span of cladding is approximately 1800 mm.Windshield cladding is also available with perforated designs for specific ventilation situations. If openings in the cladding are required, we can also provide cladding with windshield doors (both sliding and hinged types).

Blast relief cladding

Blast relief cladding is based on windshield cladding with the addition of blast relief bolts. The blast relief bolting is designed in-house by InterDam. When required, the cladding can be designed to remain in place during a blast event.Heatshield cladding

Heatshield cladding panels are based on a single skin type (stainless steel 316L) and supplied complete with framing, if required. The panels are bolted to back-up framing. The heatshield panels will meet the following criteria (at a minimum):- Up to a 75% reduction in radiation from the external face to the internal face

- Visibility through the panels

- Natural ventilation through the panels

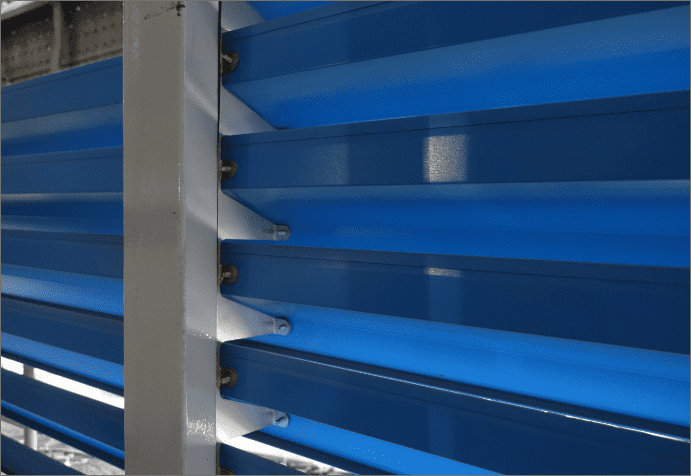

Louvres

Louvres are a prefabricated system made from aluminium, stainless steel or pre-coated galvanised steel consisting of louvre blades with brackets or a completely framed design. Louvre design is optimised with regards to pressure drop and air flow. The blades will be a profiled type and fixed by either welding or bolting to the panel framing.Cladding types

Key features of our cladding systems

- A1 and A2 fire rated

- We utilise composite materials for their strength, allowing the cladding to endure extreme offshore wind forces.

- Customization: Our cladding panels can be tailored to specific project requirements, ensuring optimal fit and performance.

Applications of cladding

Key applications include:

- Offshore oil and gas platforms

- Petrochemical plants

- Power generation facilities

- Industrial complexes

InterDam’s commitment to excellence

At InterDam, we understand the unique challenges of fire and blast protection. We continually invest in research and development to offer cutting-edge solutions, and our products undergo rigorous testing to ensure they meet the highest safety standards, serving clients worldwide.

In-house design and manufacturing

InterDam prides itself on its in-house design and manufacturing capabilities. Our team of experienced engineers and technicians works collaboratively to develop innovative cladding solutions. By controlling the entire process from concept to production, we ensure quality, precision, and the ability to customize products to suit the unique needs of each project.

Shipping, installation, and maintenance

InterDam products are designed with the full life cycle in mind, including installation and maintenance. Installation of certified products requires skilled personnel. We provide on-site supervision or dedicated installation teams upon request. Following the detailed installation instructions ensures that the products are correctly fitted and maintain their fire and blast ratings.

Ongoing maintenance is essential to ensure long-term performance. This includes routine inspections and maintenance to ensure compliance with the latest safety standards. Maintenance instructions are included as part of our supply.

Ongoing maintenance is essential to ensure long-term performance. This includes routine inspections and maintenance to ensure compliance with the latest safety standards. Maintenance instructions are included as part of our supply.

Ready to enhance your facility’s safety and compliance?

Contact us today to learn more and how we can tailor a solution to meet your specific requirements.

References.

Heerema Marine Contractors, Thialf

Neptune, F3-FB

TAQA, Platform P18 and P15C

Image source: TAQA

Petrogas, Haven/Helder/Helm

Ineos, Kinneil FOB Office

Arctic LNG Project

Du Pont, Hot Oil Annex

Image source: DuPont

Shell, Leman

IOG, Southwark & Blythe

Image source: blythe

Total, Tyra Redevelopment Project

TCO, Tengizchevroil Future Growth Project