In this article InterDam’s Noud Riemens and Rob Dedden elaborate on optimization practices for crimped blast and fire wall design. For larger projects partitioning of design cases into a smaller number of cases strikes the right balance between material cost savings and project complexity. This article presents a comprehensive design strategy for these challenging projects, as well as for smaller scale projects.

Abstract

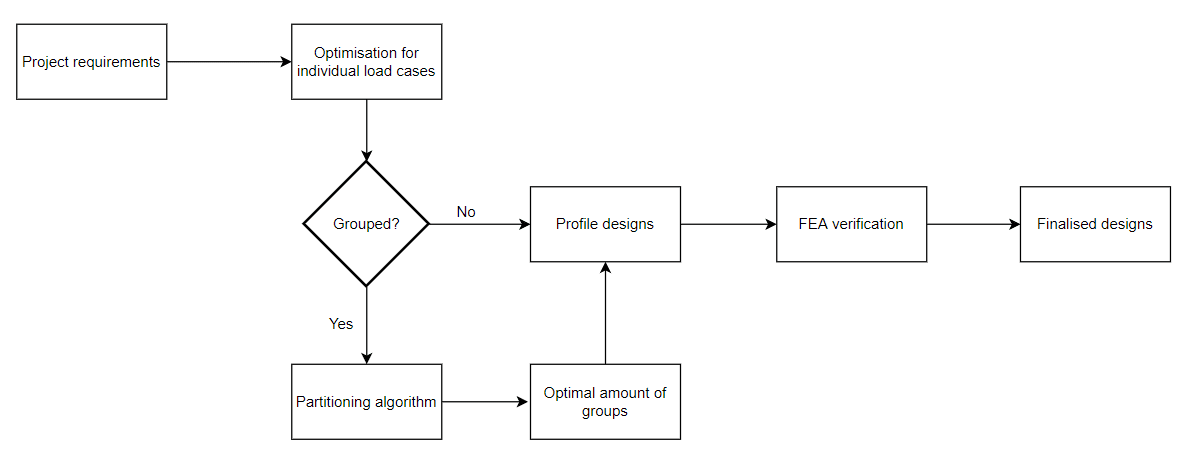

The design of corrugated blast walls can be challenging but the availability of detailed blast information offers opportunities for economic design. However, for large projects, the number of distinct design cases makes it time-consuming to achieve this by manual trial-and-error. Furthermore, it is inefficient to design a different profile for every individual design case. Partitioning the design cases into a small number of groups, each with a distinct blast wall design, strikes the right balance between material cost savings and project complexity. This paper presents a comprehensive design strategy (see figure below) for these challenging projects, as well as for smaller scale projects.

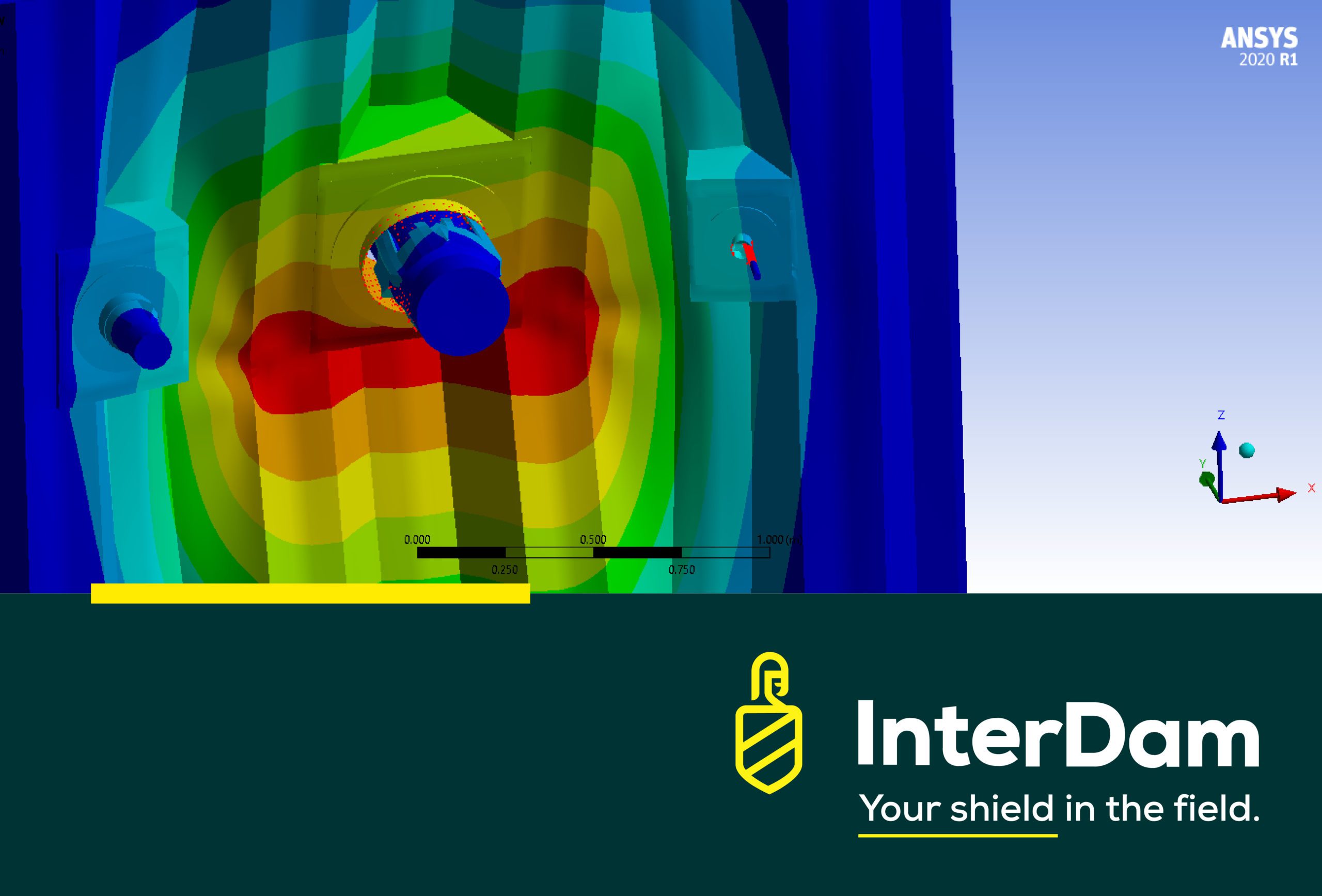

For projects consisting of a few design cases, profiles can be verified for each case individually. Optimisation for individual design cases is done by brute forcing a large set of profile options and selecting the lightest one that meets all design case requirements calculated using the SATEL model (www.blastresponse.com). In the case of larger projects, the design cases are partitioned using a binary integer programming problem, and an optimised profile is returned per group of design cases by a slightly extended version of the brute force approach. The resulting set of profile designs is verified against specification using explicit Finite Element Analysis.

As an illustration, two individual design cases have been optimised. Compared to previous methods, material cost savings of 10.1% and 31.7% are achieved. Furthermore, partitioning a large scale project using the binary integer programming method result in material savings of 14.9% Altogether, the automated design methods results in safe and verified designs, while allowing significant cost and weight savings for projects of any size and complexity.