Fire- & blast

resistant walls

Safety solution for all

situations

Where and why to install blast-proof walls

- Offshore platforms: The harsh offshore environment demands solutions that can withstand fire, explosion, and corrosion. InterDam’s blast walls are particularly suitable for offshore applications due to their lightweight design, while also offering fire-post-blast capabilities that give operators critical time to respond during emergencies.

- Industrial facilities: For chemical plants and energy facilities such as LNG plants or hydro-power plants, fire-rated access panels and blast-proof walls are essential for protecting both personnel and equipment. Our systems are designed to be easy to install, reducing complexity and ensuring that even last-minute modifications can be accommodated.

- High-risk zones: Areas like control rooms, research laboratories, military installations, and hazardous material storage spaces benefit from our fire safety walls, which combine blast protection with fire resilience to provide comprehensive coverage.

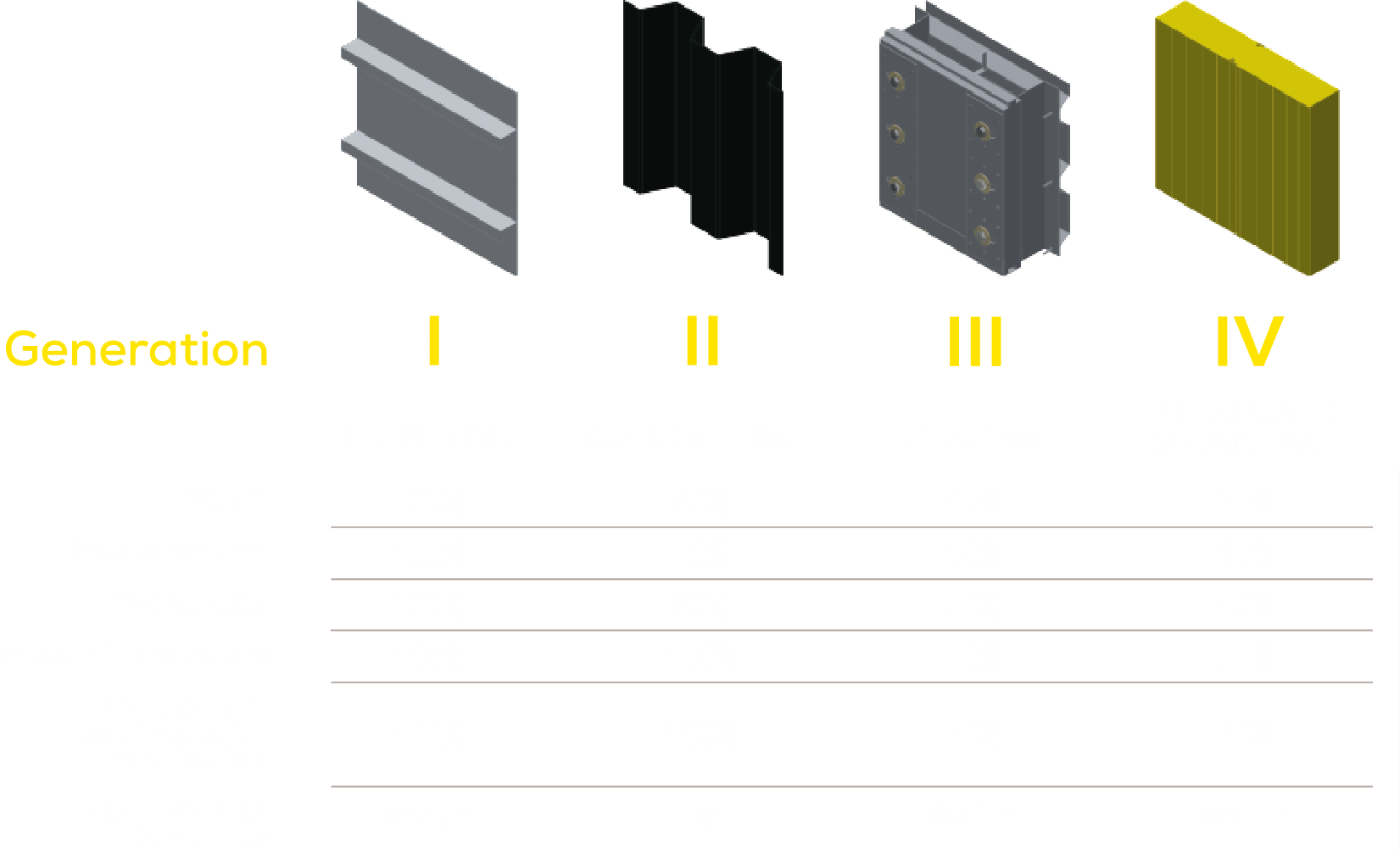

Bolted and welded walls, easy installation, low weight and increased cost-efficiency. Blast resistant/blast relief.

Generation

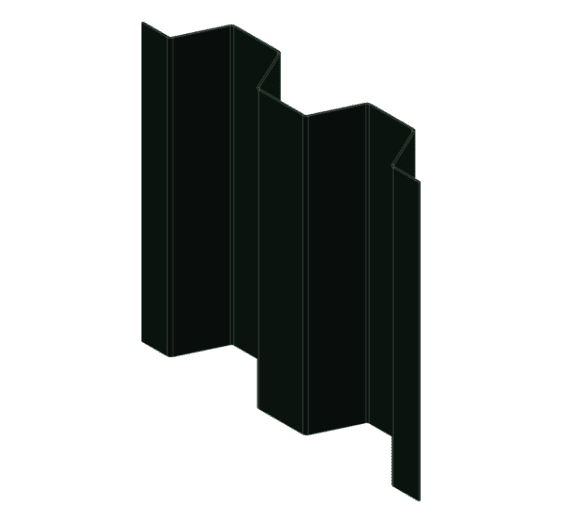

II

Corrugated wall.

Traditional solution for applications with high blast loads

InterDam has extensive experience with the design, manufacture and supply of corrugated fire and bast walls. Our structural engineering team can optimize grade and weight of steel required for your project using inhouse optimization software. This leads to the lowest cost option for your project. Blast loading up to 2.5 bar has been tested and fire ratings from A0 to H120 and Jet Fire are available

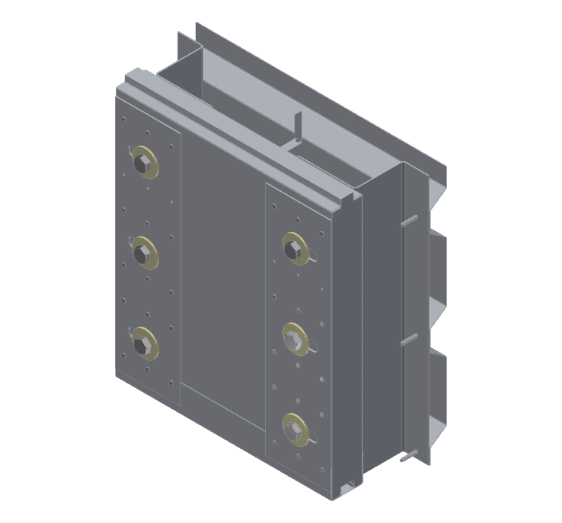

Build-up wall.

Fire-Post-Blast protection

InterDam’s Generation III walls provide maximum protection for a fire following an explosion, whilst reducing weight compared to Corrugated Wall systems. The use of a bolted construction also reduces the amount of welding required compared to Generation II wall systems.

Generation

III

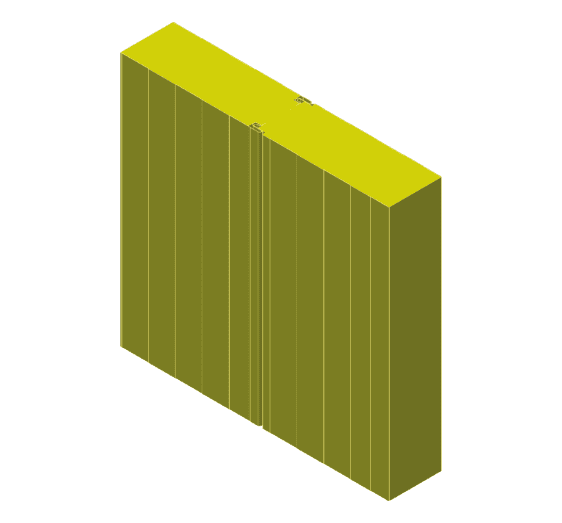

Generation

IV

Prefabricated

sandwich wall.

Lowest cost solution for fire and blast walls

InterDam’s innovative G21 Fire Panel and Blast Panel provide the ultimate in weight-saving, ease-of-installation and cost saving for both onshore and offshore applications.. Available for A0, A60, H60, H120, J30 and J60 fire ratings and blast loadings up to ~1.0 bar, our lightweight sandwich panels are quick to install and allow for penetrations to be placed after the panels have already been installed. As well as speeding up construction during new-build, the G21 panels are ideally suited for retrofitting applications as they can be installed as a bolted solution, removing the need for hot-work in an existing facility.

G21 panels are certified for internal and external walls, for onshore and offshore application and for fire and blast protection.

Tests and compliance

InterDam’s G21 series offers cutting-edge fire and blast wall panels that are rigorously tested for both static and dynamic loads. Our systems are validated for wind pressure, temperature loadings, and have proven airtightness capabilities. Additionally, our panels feature innovative designs like the Blast Interface Rails (BIR), which enhance structural integrity in blast scenarios.Certifications

Our walls are certified to meet the stringent standards set by authorities like DNV-GL, ABS, USCG, and Lloyd’s Register. They have undergone tests for fire ratings, blast resistance, and overall durability, ensuring compliance with the highest industry benchmarks.The following video shows various tests:

Easy installation and maintenance

InterDam’s wall panels are delivered fully prefabricated, reducing on-site labor and ensuring consistent quality. Installation is straightforward, requiring no hot work, and our systems can be visually inspected to ensure proper assembly. The G21 Fire Panel allows you to install penetrations in situ and at the last minute. Moreover, maintenance is simplified through detailed guidelines, making it easier to extend the lifespan and performance of the wall systems.

Our G21 Fire Panel systems are designed with a lifespan of up to 50 years in non-marine environments (internal offshore walls and external onshore walls) and 30 years in marine environments (external offshore walls). This longevity is achievable when installed and maintained by InterDam-certified engineers.

Customizable solutions for every need

Every project is unique, and so are our wall systems. Whether you need a specific fire rating, a lightweight design, or a wall that can withstand both blast and fire, InterDam offers customizable solutions to meet your exact requirements. Our walls are available in various materials, thicknesses, and profiles, allowing us to tailor the solution to your project’s specifications.

Why choose InterDam?

When safety is non-negotiable, InterDam’s fire and blast-resistant wall panels provide the protection needed to safeguard both people and assets.

Key benefits include:

- Advanced heat shielding: Our exterior wall heat shields and heat shield wall panels are engineered to resist high temperatures, ensuring the structure remains intact during intense heat scenarios.

- Fire- and blast resistance: The G21 wall series provide significant protection against high overpressures, making them ideal for blast zones. These blast-resistant walls are extensively tested to offer protection even under extreme conditions. With fire ratings from A60 to H120, our panels are also designed to resist fire post-blast. The use of mineral wool core material ensures excellent thermal insulation and non-combustibility.

- Fire post-blast capabilities: InterDam is the first company that has tested its products to withstand not only the impact of a blast but also a subsequent fire outbreak. Unlike most solutions that can withstand either a blast or a fire but not both consecutively, InterDam’s G21 Blast Panels are specifically tested for both scenarios. After enduring a 0.25 bar overpressure blast, our panels maintain their fire resistance, achieving ratings of H120 and EI240 (H240) after exposure to a hydrocarbon fire for 240 minutes. This dual protection is crucial in giving personnel additional time to escape or implement emergency procedures in high-risk situations.

Contact us

Ready to enhance the safety of your project? Contact us today to discuss how our industry-leading fire and blast-resistant wall panels can protect your assets and ensure the highest safety standards.

Our references

Image source: TAQA

Image source: Smulders

Image source: Shell

Image source: DuPont

Image source: Sabic

Image source: blythe