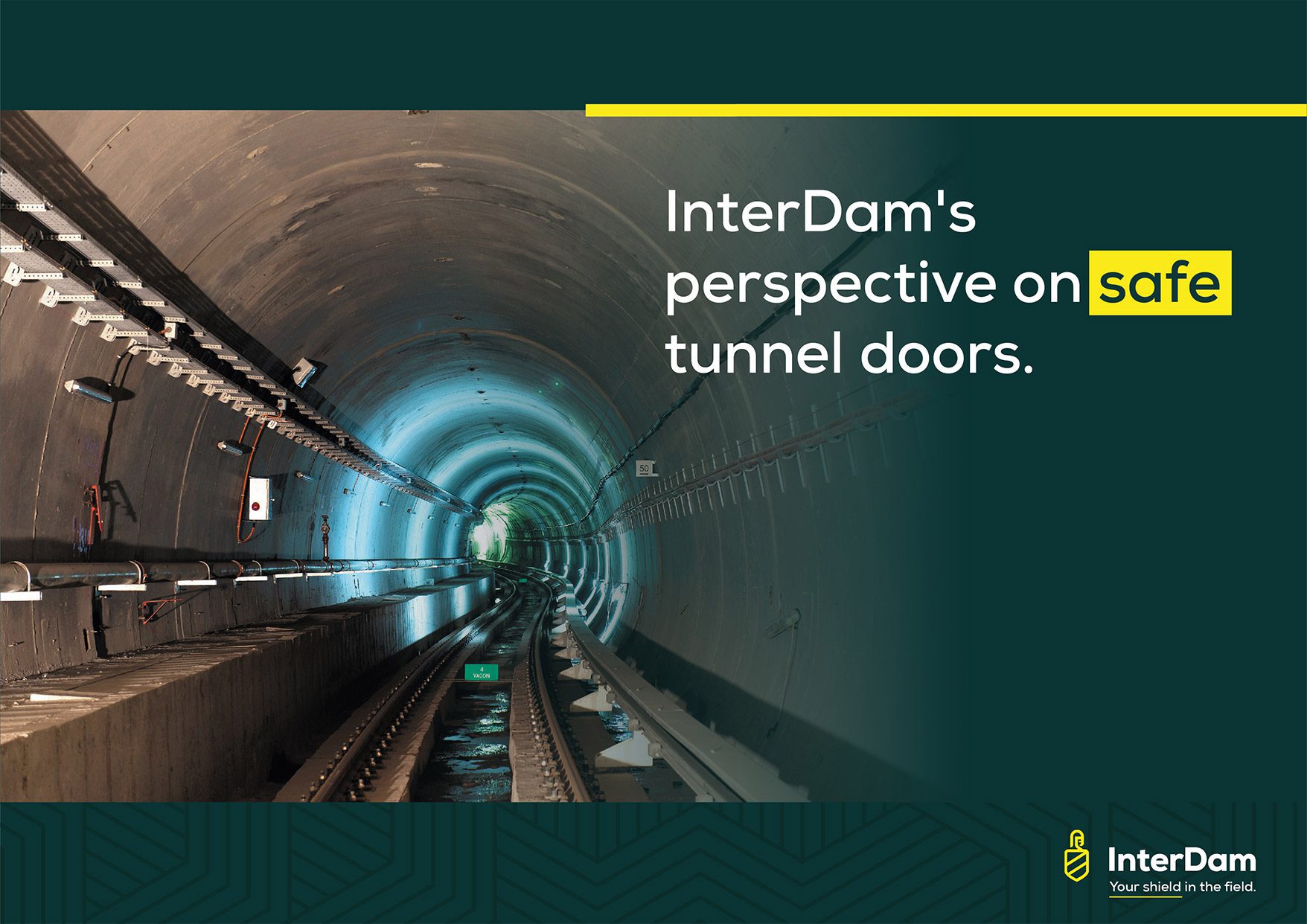

The lack of space and urban needs have accelerated the digging of tunnels and underground spaces. Today the world digs 5.200 kilometers of tunnels per years. The world builds tunnels but it also need to make them safe for users.

InterDam’s perspective on safe tunnel doors

In the past few years, the evaluation of a number of accidents resulted in more stringent fire safety requirements. Tunnel doors form a critical part of the tunnel safety philosophy.

The global tunnel fire door industry is strongly divided and the regulations differ from country to country. This makes it hard to find economies of scale in the production of tunnel fire doors.

Many of the current doors that are installed in tunnels require frequent maintenance, the main reason is the philosophy of low maintenance during the production. Our goals is to lower maintenance cost by investing on more durable product and therefore increasing the CAPEX.

Regulations are not standardized in all countries. Every country is prescribing different fire ratings. Our strategy will be to develop a “Global” standard set of tunnel doors that are tested according to the Mother Of All Curves (MOAC). Producing these type of doors allows us to be THE solution for every country, because even the countries with other local requirements will be able to use our doors. Thanks to the economies of scale we’re going to produce a new generation of tunnel doors.