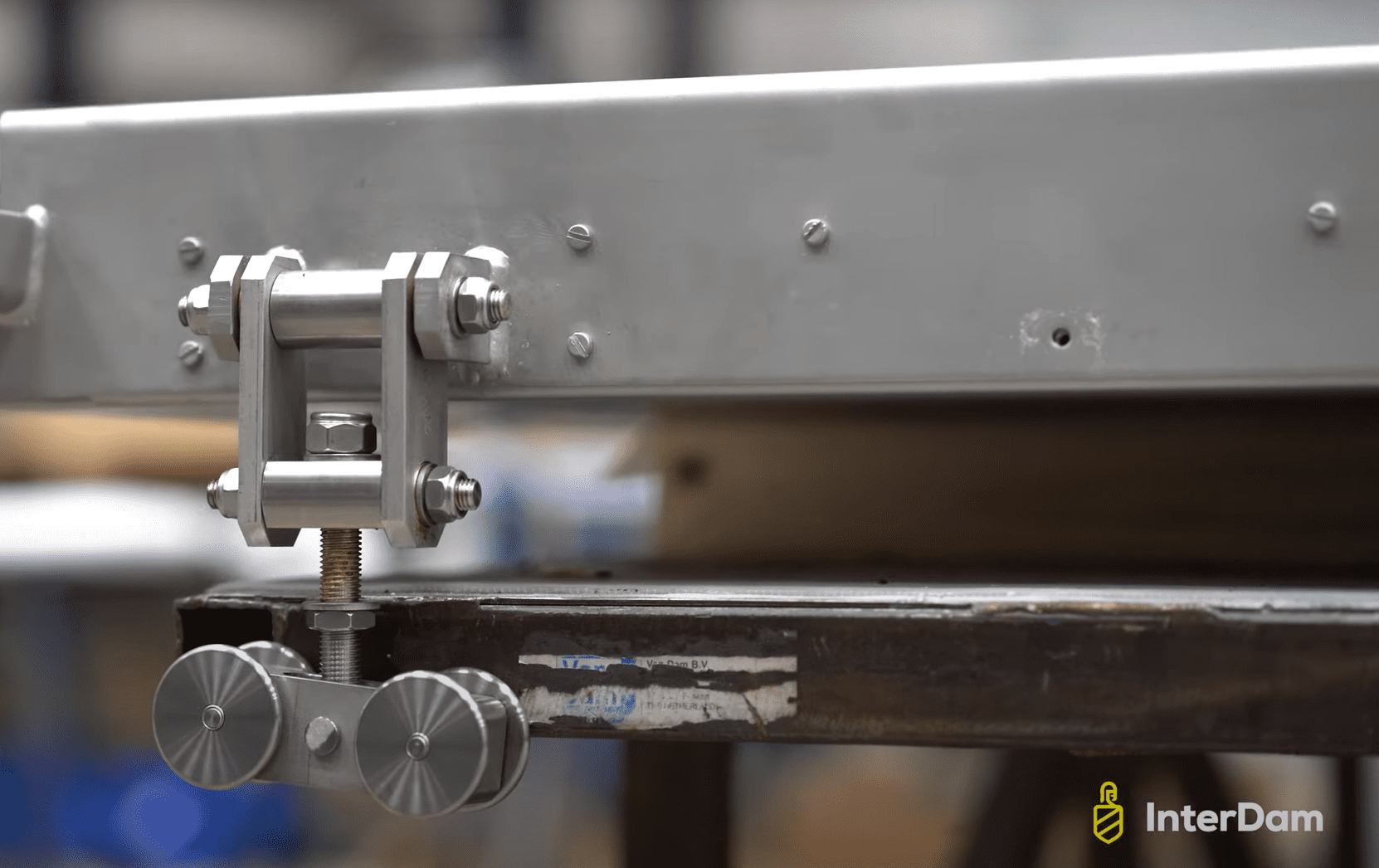

InterDam fire- and blast resistant doors are built to last for decades, if properly maintained. Recently InterDam was approached by one of our customers with the question if doors manufactured and installed in 1998 could be refurbished to last for another 20 years. The doors had been working to satisfaction for the past 25 years and by extending their life the customer could reduce costs, waste, and the carbon footprint of manufacturing new doors. After a thorough investigation by InterDam, it was concluded that the structural integrity of the doors was still extremely solid and that only the moving parts and the pneumatic operation required overhauling.

By refurbishing these doors InterDam was able to reduce delivery time, lifecycle costs and contribute to our and our customer’s sustainability goals through a drastic reduction in the use of raw materials and energy required. And, of course, the safety of the assets would also be maintained at the highest possible level.

Interested? Our Maintenance & Repair team is available to inspect your passive fire- and blast resistant architectural assets and present the possibility.

#InterDam #YourShieldInTheField #Sustainability #Refurbishment #Maintenance #MaintenanceAndRepair #Manufacturing #FireAndBlastDoors #FireDoors #BlastDoors #G21FireDoors #CarbonFootprint #LifeCycle #LifetimeExtension #PneumaticOperation #Reuse